Hey guys,

I’m trying to solder one of the XT60 cable to my ESC pad,I used flux pen on the pad also on the cable, ironned both cable and pad,put a tip of solder on the edge of the iron solder after I shined whole of it with iron and sponge, then after all the preps, I can manage to solder a little on the pad, but as soon as I attempt to connect it to the batt cable, the solder on the pad sticks to the cable and just slips from the pad, doesn’t stick at all, what can I do?

Tried to rub the pad a little with some metal a little to charge it with negative charge.

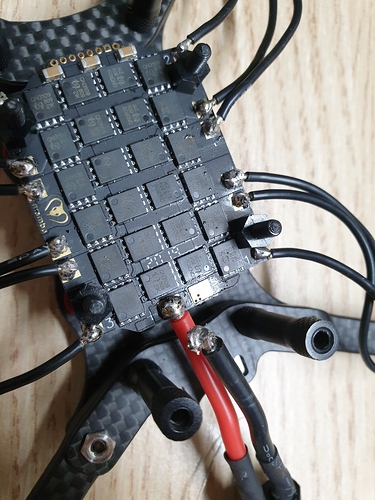

arh the negative pad on a 4in1

The Negative pad has more copper to it than any other pad… its massive its like a big heat sink.

You need heat LOTS of heat.

Flux, + 450c iron + big tip.

I’m no solder expert but thats what I would try…

@Maximilian what would you do?

The negative pads are all linked across the board so you basically need to heat the whole board up to get the pad hot enough for the solder to adhere. The reason why the solder is running off is because the pad has not got hot enough.

You need to heat neg pads for longer. Soldering iron at 450 degrees, small blob of solder on the iron to conduct heat, hold it on for a few seconds then push a bit more solder in. It will seem to stick to the iron and not the pad. Keep the iron on and when the pad gets to temp the solder will suddenly flow onto the pad. At that point push more solder on to tin the pad.

At this point I would get the wire on to prevent having to reheat.

If you do need to reheat to get the wire on, push the iron into the pad and lay the wire on top of the iron until both become fully molten and then remove the iron letting the two bond.

What type of solder are you using? Much of it depends on the working temp of the solder.

This is what I tought its not too hot, but I was afraid to do damage to the board from too much heat, actually I dont know which kind of solder I’m using, I used it a lot recently.

Which do you recommend?

Edit: Managed to do it thanks for your help guys!

Like Maxim said, heating the pad more did the job.

YAY! Got it sorted, happy days and well done. Hardest part to this lark is getting the technique for neg’s down. In the mean time, just get this stuff, its bloomin’ brilliant ![]()

Also, always use multi-core solder with lead - none of that crap ‘lead-free’ stuff.

The lead-free solder doesn’t flow as well, and hardens at higher temperatures.

In short use higher soldering temperature(higher wattage"60W") to experience less temperature drops. Flood the pad with solder flux. 60/40 lead is ideal but higher tin solder is better(shy away from lead free stuff). Lastly if you have low wattage iron, hold the iron for longer period but it’s not ideal due to components being sensitive to high temperature. I suggest that you invest into a 60W iron but a temperature controlled one is ideal like the TS100 iron. Hope I helped somehow.

Before you try soldering the pad to the board you should tim the pad first,

1st using a high wattage soldering iron at least a 40 watt set the iron to a high temperature clean and tin the iron give the pad a quick rub with a little sandpaper to take the oxidation off it once the iron is hot put it on the pad and hold it there for a few seconds then apply solder and keep the iron on until the solder has covered the pad then remove the iron then put the tinned wire on the pad and put the iron on the top of the wire and wait until all of the solder from the wire and pad have started to flow if needed apply a little more solder if not once the solder flows remove the iron but do not allow the wire to move until the solder cools down or you can end up with a dry joint where it looks like it is attached but when you try to apply current it will just fall off.

hope this helps.

It looks like everyone is of the same mind the new lead free solder is crap I agree it may sound like it should be better but it is a waste of time.

I also do not like lead free solder. It always feels like the iron is not hot enough and frequently ends up with spiky, nasty looking joints.

I’d also agree that a pretty hefty iron is needed to make a decent job of soldering thick cables onto high power boards. 60 watt minimum. 80 or 100 watt better. The quicker you make the joint, the less the heat penetrates into the PCB and the less chance of damaging it.

This topic was automatically closed 3 days after the last reply. New replies are no longer allowed.